Business segment - 2

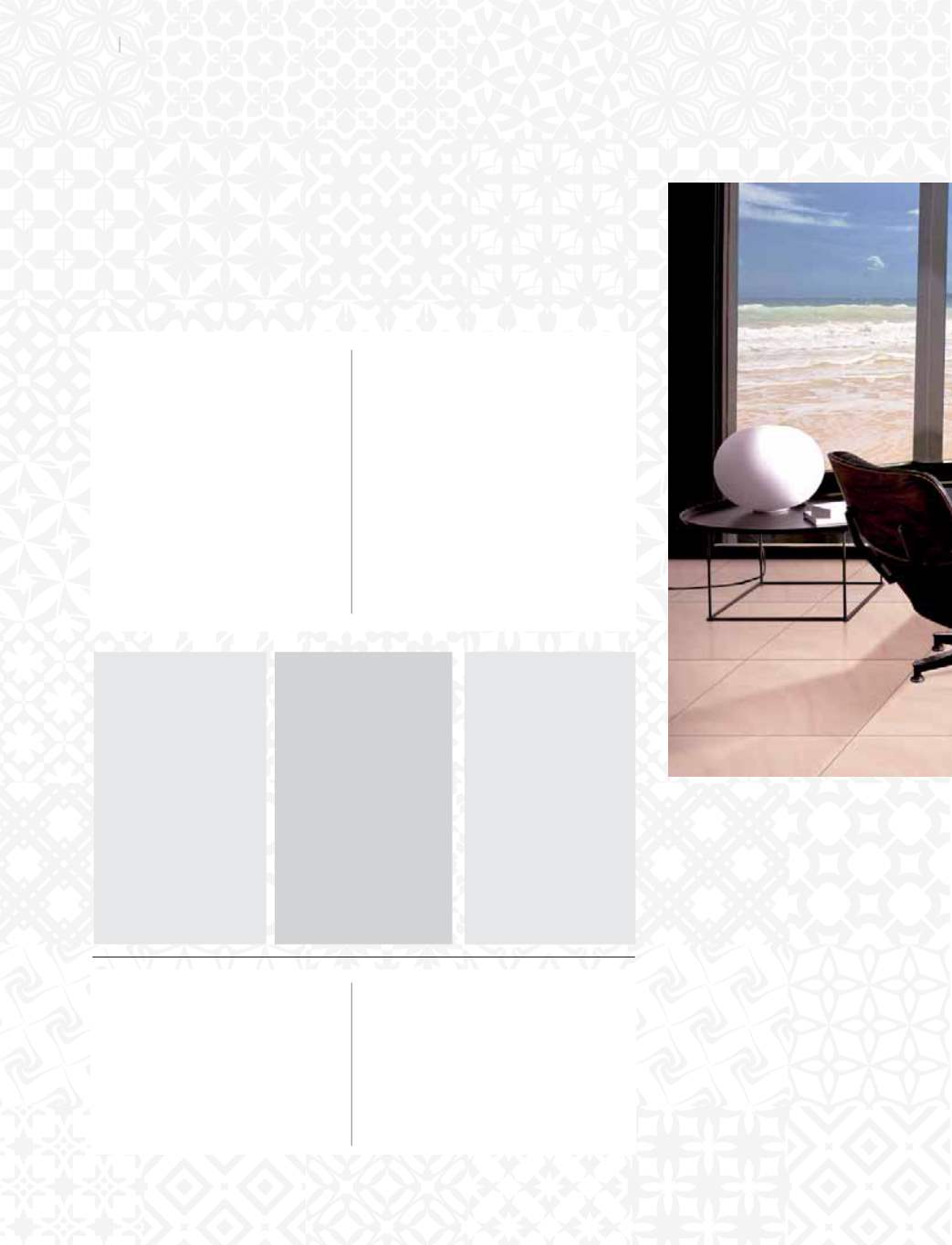

Polished

vitrified tiles

Business in 2013-14

Sales volumes and value increased by

16% and 14% respectively over the

previous year despite a production

disruption in Morbi.

Overview

Kajaria manufactures polished vitrified

tiles at its Gailpur, Jaxx and Cosa

facilities, which allows it to address

its pan-India distribution network. Its

wide tile variety is marketed through

Kajaria Galaxy and Kajaria Studio

chains as well as the pan-India Kajaria

dealer network.

Product attributes

Polished vitrified tiles are considered

‘next generation flooring’ marked

by a polished surface, high gloss,

extraordinary quality and durability.

They are designed to withstand

abrasion, chemical resistance, fire

and staining. There are three different

varieties in this segment

Performance in 2013-14

Making our business more

competitive

Replaced the import of soluble salts

from China with outsourced products

from Morbi; streamlined logistics and

distribution channels, which reduced

the lead time between the Morbi

plant and dealer warehouse; reduced

the depot sizes, which optimised

distribution costs

Streamlined operations at the Gailpur

unit to enhance productivity; replaced

natural gas with coal gas in spray driers

to optimise production costs

Soluble salts

Vitrified

tiles

that are

printed with screen

printing technology and

then polished are called

soluble salt vitrified tiles.

Low-end vitrified

tiles

in India

Limited design options

due to technology

limitations

Double charge

Vitrified

tiles

where the

press feeds two colours

on the tiles bisque and

makes a 3-4mm thick

layer of design on the

top.

These tiles

have a

longer life than soluble

salt tiles

Limited design options

due to technology

limitations

Full body vitrified

tiles

Vitrified

tiles

have

colour throughout the

body (thickness) of the

tile. Because of this

chipping or scratches

are less noticeable

Design

will never fade

Ideal flooring

which

can resist heavy traffic

areas such as shopping

complex, airports etc.

22

Kajaria Ceramics Limited